When motor shaft voltages exceed the insulation capacity of the bearing grease currents directed to the outer bearing can occur and cause pitting and grooving on the bearing races. Adding Grease to Electric Motor Bearings Electric motors utilizing double shielded or double sealed bearings which are typically of the lubricated-for-life design usually do not require regreasing.

Electric Motors Simpson Machinery

On the other hand all others those being open or single shielded or sealed bearings should be re-lubricated periodically to replace grease that has deteriorated leaked away or become.

Electric motor failure caused by grease build up in motors. PROBLEMS WITH ELECTRIC MOTORS. Electromagnetic discharge caused by the motor Electrostatic discharge belts cylinders etc External voltages VFD welding etc Electric discharge can cause pitting in rolling elements as charges arc through the lubricant film from the rotating shaft to ground. Motors need to be inspected regularly and other maintenance activities need to be performed to ensure efficient operation.

Start-up and operation vary greatly and influence the motor load carrying capacity. Regreasing with the wrong grease can lead to premature bearing failure. Electric Motor failure occurs due to overheating phase unbalance voltage unbalance single-phasing surge voltages poor ventilation lack of lubrication overloads over cycling excessive moisture improper belt tension misalignment and vibration loose connections pests etc.

However a few basic precautions should be taken. They also point out that if I re-grease the thing the warranty will be void. Therefore improperly greasing your motors is bad.

Feel for air being discharged from the cooling air ports. On the other hand over-lubrication can also. So now that we know why we need to grease motor bearings how can we make sure we include greasing the motors as part of our preventive maintenance strategies.

Grease Incompatibility - Greases are made with different thickeners such as lithium calcium or polyurea. Amount of grease could lead to bearing failure due to lack of lubrication. Mechanical Problems EDM or Fluting Fluting is caused by one of the following.

When contaminants stick to your motor rotors fan blades or other rotating components they add excess weight. Re-greasing Intervals Electric motors utilizing double shielded or double sealed. The bearing lubricant is contaminated.

Summary of motor stresses. Whenever a problem occurs it should be corrected immediately to avoid further loss. Electrical motors are wonderful devices that are used in a myriad of ways making things easier in our daily lives as well as a wide range of industrial applications.

Wipe brush vacuum or blow accumulated dirt from the frame and air passages of the motor. Heat reduces insulation life and eventually causes motor failure. This added heat will eventually break down the mechanical and electrical components of your motor and can lead to motor failure.

Once all excess grease has been expelled you can go ahead and replace the relief plug. Motor failure however we choose to define it is a result of improperly greasing critical motor bearings. Electric motor grease is in the range of 500 to 600 SUS at 100F.

Motor failure is bad. There are six main causes of electric motor failures. Below are a number of problems that are often encountered when using electric motors.

When you take a smart approach optimizing how much and when the grease is added you will see an improvement in the useful life of your equipment better efficiency and reduced maintenance costs both in terms of downtime and electric motor repairs. Excess grease can also cause the motor to overheat increasing the risk of lubrication starvation and even bearing failure. Common Causes of Electric Motor Failure Operational overloads which can account for up to 13 rd of all motor failures and occurs when your motor is under an excessive load that leads to electrical overloads insufficient torque andor eventual overheating that can wear down components like bearings motor windings and more.

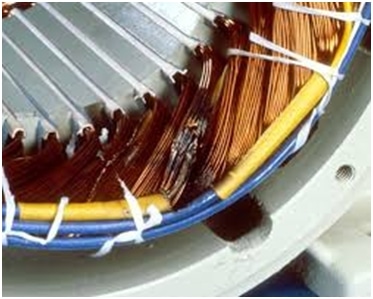

Into the motor will go between the stator coils or into the terminal box and short circuit and burn out the motor. When these gadgets fail work often grinds to a halt till theyre back up and running and the reasons for electrical motor failure can range from the commonplace to the bizarre. Common Causes of Electric Motor Failures.

Incorrect Electric motor selection for the application and motor defects can. Ive bought a Bafang mid-drive and recently asked the supplier what kind of grease is used in the motor -- the response was that they dont know but will enquire if I wish. These currents are caused by the build-up of electrostatic energy in the machines rotor which abruptly discharges when the electric field is sufficient to crack the insulating grease of the bearings.

There are a host of reasons why you want to avoid over-greasing the bearings in your electric motors. Overloading is the leading cause of electric motor failure. Most oil suppliers have grease that is specifically designed for electric motors which is different from their multipurpose extreme purpose EP grease.

Creating an imbalance to rotating components. Most motor failures are caused by a combination of various. In a case where the root cause isnt as easy to determine its imperative that you complete each step of the methodology.

Failure to do so could result in no grease getting to the bearings for the first few shots as any grease that is ejected from the gun is simply filling the supply tube. First any tubing that connects the grease fitting to the motor bearing should be pre-charged with grease. Clean any grease away from the relief port and youve finished greasing your electric motor.

Ive read a few mentions of noisy motors and references to alternative lubrication. Dirty motors run hot when thick dirt insulates the frame and clogged passages reduce cooling air flow.

The Essential Guide To Electric Motor Failure Duke Electric

3 Common Causes Of Electrical Motor Repair Kurz Industrial Solutions

Electric Motor Failure Causes Electrical Academia

Conductive Lubricants Protect Electric Motors

5 Things That Commonly Cause Electrical Motor Failures

Motor Maintenance How Much Grease Is Too Much

Causes Of Faults In Electric Motors And Their Effects

Selecting And Maintaining Electric Motors And Controls Unit

A General Guide To Dc Motor Maintenance Ohio Electric Motors

Make An Electric Motor Run Again 6 Steps With Pictures Instructables

Maintenance And Troubleshooting Of Electric Motors Maintenance Worldmaintenance World An Article Source For Reliability And Maintenance Management Professionals

The Essential Guide To Electric Motor Failure Duke Electric

How To Wire An Electric Motor To Run On Both 110 And 220 Volts Hunker Electric Motor Home Electrical Wiring Electricity

Industrial Motor Control The Motor And Starting Methods

Electric Motor Failure Causes Electrical Academia

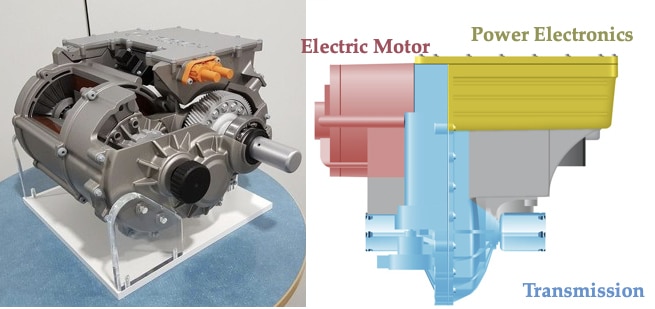

Demystifying Emc In An Electric Vehicle S Drive Unit Interference Technology

Komentar

Posting Komentar